1-Way Ceiling Diffuser

For all MADE TO ORDER products please complete the request form at the bottom of the page or call us.

Including diffusers, egg crate grilles, double deflection grilles, return air grilles, louve grilles and circular diffusers.

1-Way Ceiling Diffuser

2-Way Ceiling Diffuser

3-Way Ceiling Diffuser

4-Way Ceiling Diffuser

Ceiling Valve

Circular Louvre

CVBF4W Bevel Face 4 Way Diffuser Plastic

CVECCS1200 Egg Crate Core Sheet 1200mm x 1200mm

CVMDO Multi Directional Outlet

Double Deflection Grille

Egg Crate Grille (White)

Extract Valve

Extract Valve (Fire Rated)

Fixed Blade Grille

Floor Grilles

Flush Mounting Egg Crate Grille

Flush Mounting Grille

Gravity Louvre Shutter

Jet Nozzle Diffuser

Linear Bar Grille

Metal Flap Louvre Shutter (Black)

Multi-Cone Diffuser (Fixed and Adjustable)

Non-Vision Grille

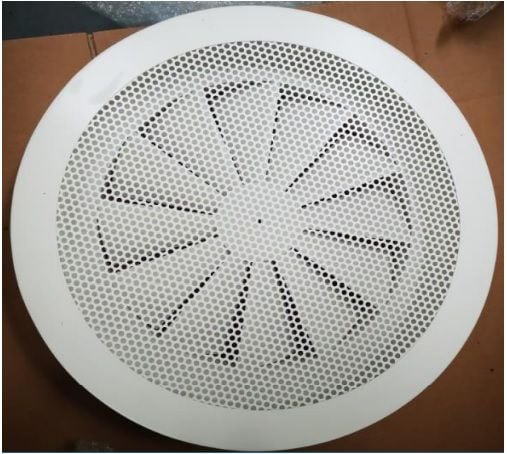

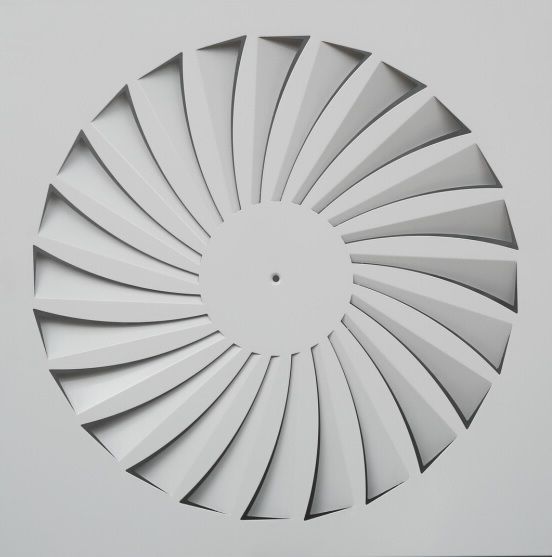

Perforated Face Swirl Diffuser - Round

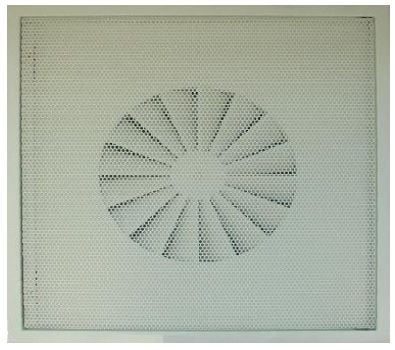

Perforated Face Swirl Diffuser - Square

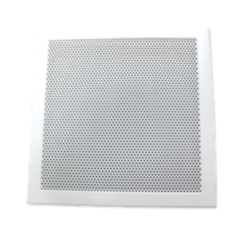

Perforated Grille

Return Air Grille

Round Jet Diffuser

Single Deflection Grille

Slot Diffuser

Spiral Duct Mounted Double Deflection Grille

Supply Valve

Supply Valve (Fire Rated)

Swirl Diffusers (Circular and Square)

Weather Louvre

Often the air flow required will determine which air vent is suitable in terms of size. Resistance factors such as blades or dampers should also be considered when calculating the ventilation grille size you need - For example, angled blades will create more resistance than straight blades.

If you have a ventilation project and need assistance selecting the right products to suit your requirements, just contact our technical department and they will be happy to assist and guide you through the process.

One of the most important factors when considering venting and grilles is the overall finish. All of our products are available in various designs and styles; most of our standard finishes are 'Mill Aluminium' or 'White RAL 9010' or 'White RAL 9016'. All of our aluminium air vents can also be provided in anodised or powder coated to match any RAL/British Standard colour reference.

It is generally accepted that aluminium is a long lasting lightweight metal with minimal on-going maintenance requirements.

There are many different surface finishes that can be applied to enhance the appearance of aluminium; anodising, powder coating and satin brushing are just three examples.

However mill finish aluminium is not one of them! Mill finish is not an applied finish but simply untreated aluminium.

For whatever reasons some names just stick; Escalator for moving stairway; JCB for excavator etc., and mill finish for unfinished aluminium. This term often raises expectations and mistakenly leads the unwary into expecting an immaculate surface finish. So we will attempt to close the knowledge gap when it comes to the appearance of mill finish aluminium.

Once the extrusion or rolling mill has manufactured the aluminium into the desired shape and size the material is said to be in the “mill finish” condition. So what are the visual characteristics of untreated aluminium? Extruding aluminium, as opposed to rolling sheet, produces differing surface finish effects so let’s consider them separately.

Aluminium extrusions are produced by either pushing or pulling the material (in a heated/softened state) through a hardened steel die. This process produces both simple geometric shapes (aluminium angle, channels, etc.,) and the more complex ‘purpose made’ designs. All of these forms normally display longitudinal lines of varying width, texture and tone. Various surface abrasions may also be apparent. The standard architectural grade (6063) is normally quite shiny and this tends to highlight such features.

Despite these factors there are many instances where mill finish is successfully incorporated into a large number of projects (both seen and unseen). It is usually only when surfaces are going to be viewed at close quarters, either in aesthetically demanding situations or in particularly ‘aggressive’ atmospheres , that this industrial finish benefits from a finishing operation of some kind.

Aluminium sheet is produced in a similar way to flattening pastry with a rolling pin. The constant backwards and forwards rolling process reduces the material to the required gauge thickness and temper (hardness) and in so doing the sheet becomes ’polished’ to some degree. The alloy mix of the aluminium will also affect the materials’ brightness and reflectivity. Sheets will sometimes display rolling bands or stripes and may also commonly possess a grainy type finish.

A finer surface appearance can normally be achieved by selecting anodising or architectural quality aluminium. Our industry recognises that items required for these applications require a higher surface finish standard as opposed to general commercial applications.

In summary, aluminium materials that are going to be closely scrutinised would usually benefit from an applied surface finish. However there are many applications where mill finish is perfectly acceptable.

Remember we are happy to provide a sample (subject to quantity required) of any of grille in any finish to help you make a decision.

For more information on Mill Aluminium or any other finishes please speak to our sales team on 0161 336 5065.

For those colours that do not fall into the RAL/BS range, we offer a paint-matching service. Just email or call with the details of the paint to be matched, try to include:

If you have a small sample of the tile, wood/metal frame etc, simply post it to us and we will do the rest.

We can even match finishes to designer paint ranges such as Little Greene, Farrow & Ball etc.